Geehy Semiconductor has long been working in the mid-to-high-end industrial control market. In this issue, the absolute encoder, high-performance servo driver, and VFD solutions are used as examples to introduce the outstanding performance of Geehy's 32-bit APM32 industrial-grade MCUs.

Intelligent Absolute Encoder with Promising Market Potential

Considering application requirements, usage environment, and costs, Geehy provides two absolute encoder solutions:

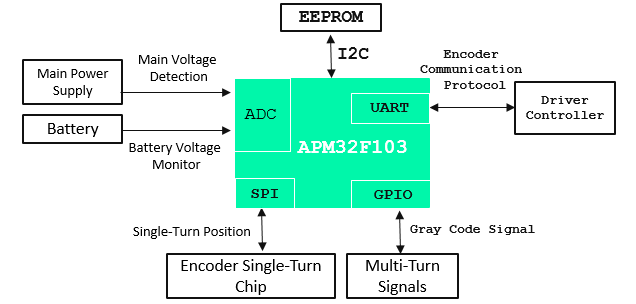

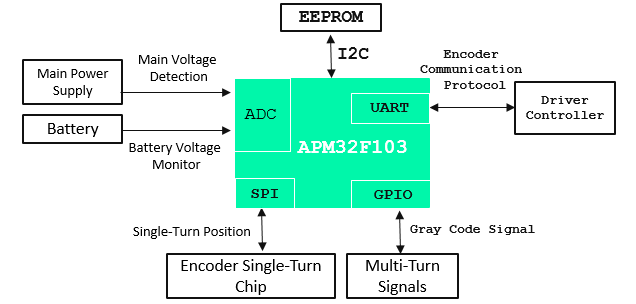

1. Used in Photoelectric and Magnetoelectric Absolute Encoders

In this solution, APM32F103 industrial grade MCU is mainly used to read single-turn position, monitor voltage, calculate the number of turns and implement encoder protocol, which needs to be used with an encoder single-turn chip.

Option 1: MCU doesn’t support position calculation

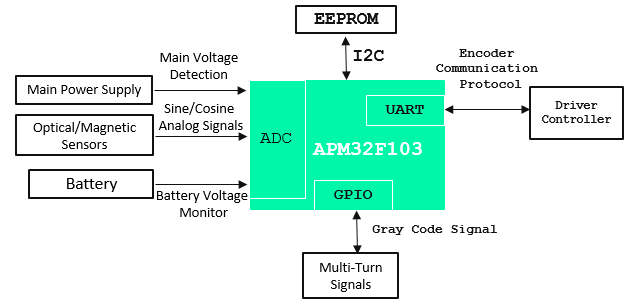

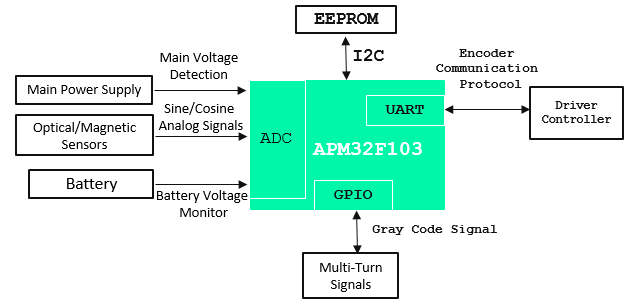

2. Used in Photoelectric Absolute Encoder

In this solution, the APM32F103 industrial-grade MCU is mainly responsible for collecting the sine and cosine analog signals from the optical and magnetic sensors, monitoring the voltage, calculating the number of turns, and implementing the encoder protocol.

Option 2: MCU supports position calculation

APM32 Absolute Encoder Solution

• Adopt APM32F103 industrial-grade MCU

• Based on Arm® Cortex ® -M3 core

• Operating frequency: 96MHz; Flash 16~512KB, SRAM 6~128KB

• 2*12-bit high-precision ADCs, support 16 input channels for high-precision dynamic real-time sampling

• 2*SPI (max speed 18Mbit/s) can quickly read and write encoder single-turn chip data

• 3*USARTs (communication rate 4.5Mbit/s) realize high-speed and reliable encoder communication protocol

• Flash (1KB) erase time ≤1.51ms, can replace off-chip EEPROM to read and write encoder register data

• Certified IEC 61508 SIL3

Integrated High-Performance Servo Drive with High Power Density and Low Cost

The servo driver is an important part of modern motion control, which controls the servo motor through position, velocity, and torque to achieve high-precision positioning of the transmission system. It's a high-end product that uses drive technology and is widely used in industrial robots, CNC machine tools, and other automation equipment.

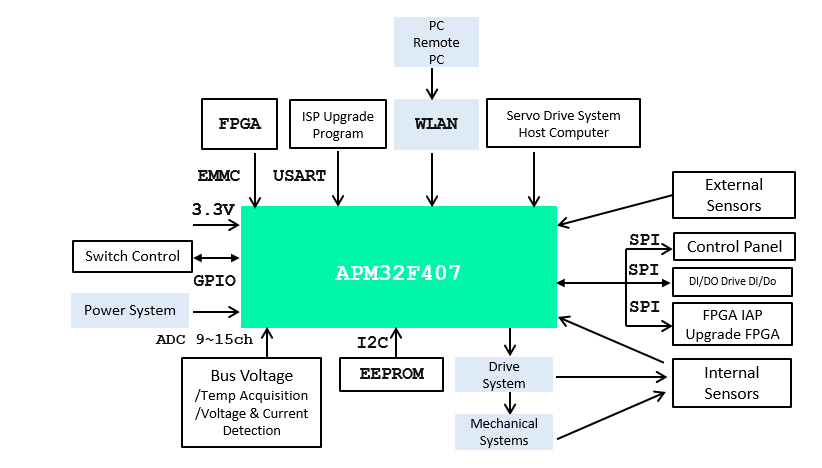

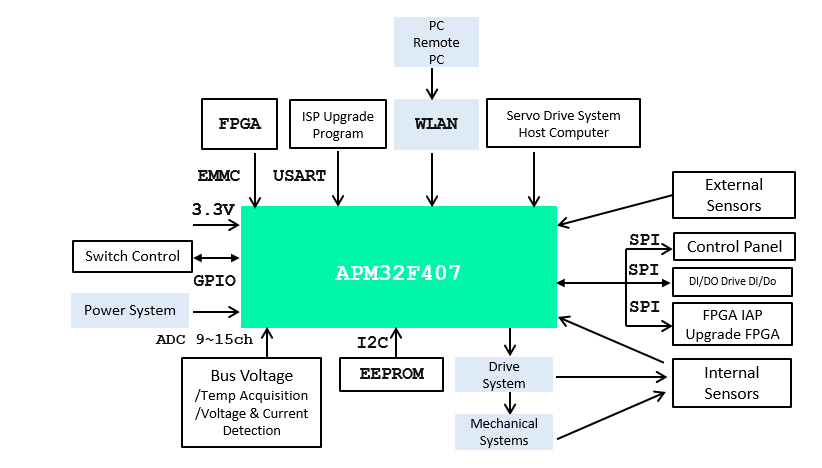

Geehy's high-performance servo driver platform supports a variety of advanced algorithms, including resonance suppression, mechanical parameter identification, adaptive notch filter, fractional-order control, PWM update, etc. With excellent performance, the current loop bandwidth is up to 4KHz and the speed loop bandwidth is greater than 800Hz. The built-in 100M EtherCAT supports a high synchronization cycle and low jitter clock. The APM32F407+FPGA+IPM architecture has powerful secondary development and flexible expansion space, which makes it easy to package, develop collaboratively and maintain.

APM32 High-Performance Servo Driver Solution

• Adopt APM32F407 industrial-grade high-performance MCU

• Based on Arm® Cortex ® -M4 core

• Operating frequency: 168MHz; Flash 1MB, SRAM 192+4KB, SDRAM 2MB (optional)

• Use CAN bus to realize motor control command transmission

• The used software makes it easy to adjust host computer parameters

• Built-in EMMC facilitates efficient communication with peripheral FPGA

• Rich peripherals support integrated motor/driver/reducer with high power density

• Use a magnetic encoder to realize position feedback, more seismic, corrosion resistance, high reliability, and simpler structure

APM32F407 is Used as A Master MCU in the Servo Drive Platform

• As an interface for human-machine interaction, a switch can control the motor's start and stop.

• Calculate to generate position references for servo drives, such as low/high speed, forward/reverse sine wave, and ramp position

• Act as EtherCAT master, detects the number of slaves, generate data frames, and transmit them through the network port

• Act as serial communication, part of the process data is sent during debugging, which is convenient for data analysis and auxiliary debugging

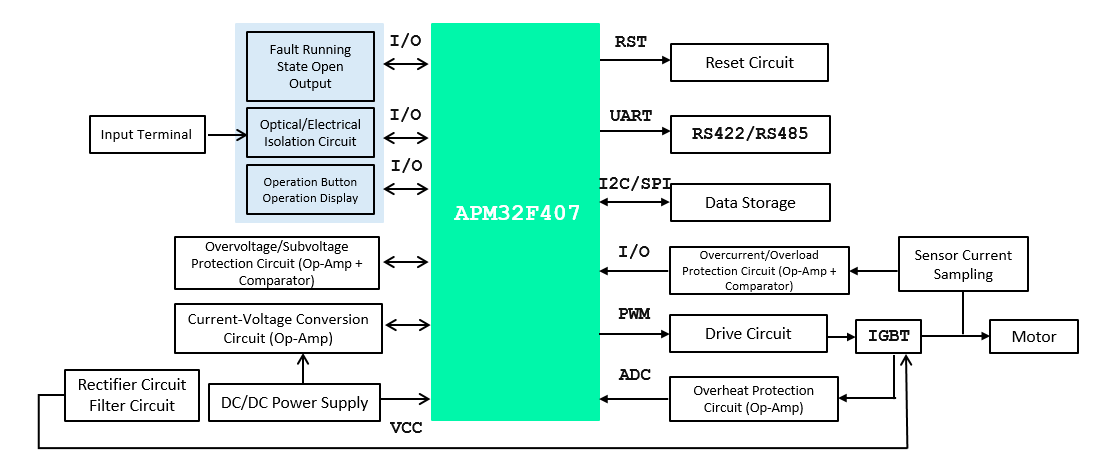

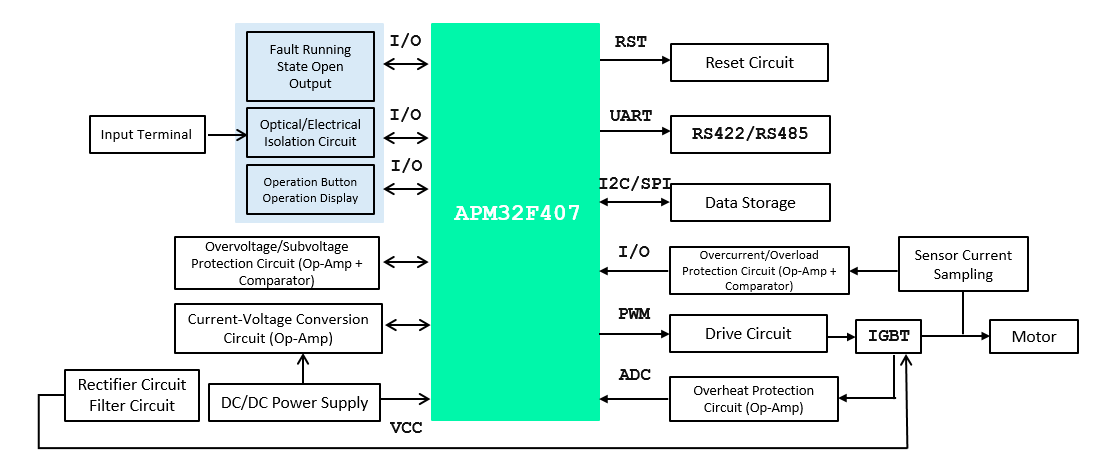

Variable-Frequency Drive(VFD) Helps Motor Reduce Consumption and Save Energy

Geehy's VFD solution can provide the required supply voltage according to the actual situation of the motor, thereby achieving saving and speed regulation.

• Adopt APM32F407 industrial-grade high-performance MCU

• Based on Arm® Cortex ® -M4 core

• 168MHz ~ 240MHz frequency, with efficient algorithm capability

• Support EMMC, PWM output, and dead-band protection

• Support vector control and V/F control

• High-speed GPIO processing response speed

• 3*12-bit high-precision ADCs improve inverter response and accurately control torque

Geehy's 32-bit APM32 industrial-grade MCU has been widely used in smart grids, PV inverters, charging piles, elevator control, instrumentation, industrial printers, and other fields and has maintained rapid growth.